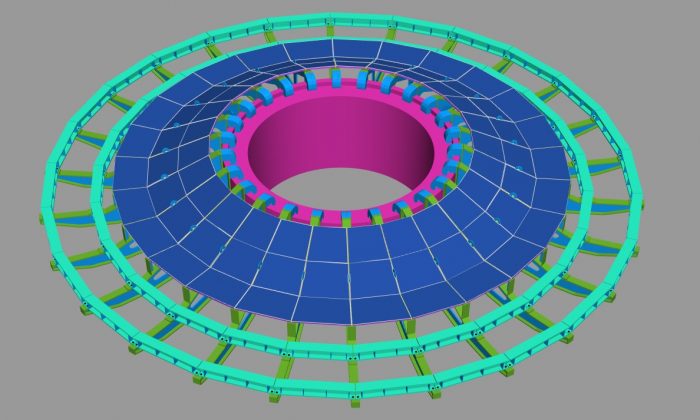

Anode Casting Wheel

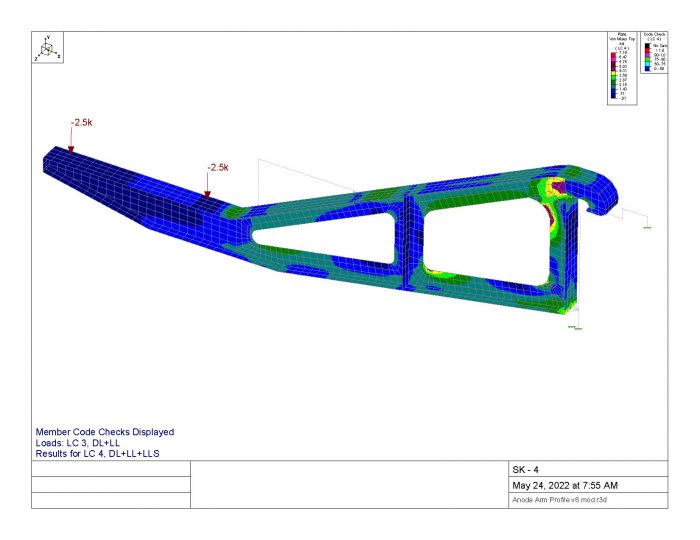

M3 was tasked with providing reverse engineering for the structural elements of an existing anode casting wheel at a copper refinery. The existing casting wheel steel is susceptible to cyclical high temperature thermal and fatigue loading in combination with exposure to corrosive chemicals; therefore, the existing steel has experienced significant corrosion. Due to the age of the existing components – 50+ years – no existing drawings or information was available. M3 completed a 3D scan of the anode casting wheel to re-create as-built drawings along with a 3D finite element analysis model. With in-house steel detailing using Tekla Structures, M3 was able to quickly generate and provide shop fabrication drawings and a contractor bid package to the owner to get the structural elements re-fabricated and installed.

- CATEGORY Manufacturing

- TAGS